Introduction

Welcome to the fascinating world of OPC UA, a game-changer in industrial automation that's been making waves for its versatility, scalability, and unparalleled interoperability. Born out of the need to bridge the gap between disparate automation systems, OPC UA (Open Platform Communications Unified Architecture) has become the go-to communication protocol for many industries, unlocking new possibilities for seamless data exchange and efficient operations.

But how did this all come about? OPC UA has its roots in the OPC Classic standard, which was developed in the 1990s to enable communication between Windows-based automation software and devices. While OPC Classic served its purpose well, it faced limitations in terms of platform independence, security, and flexibility. Enter OPC UA, a protocol designed from the ground up to address these challenges and usher in a new era of connected automation. IEC 62541 is the international standard for OPC UA (OPC Unified Architecture). The standard is published by the International Electrotechnical Commission (IEC) and is split into multiple parts, each covering a specific aspect of the OPC UA framework.

Stay tuned as we explore the remarkable features, applications, and advantages of OPC UA, showcasing its ability to revolutionize industrial automation and bring your operations to new heights.

Platform Independence: One Size Fits All

Ref: https://opcfoundation.org/about/opc-technologies/opc-ua/

One of OPC UA's most impressive strengths is its platform independence, which allows it to work across various platforms and operating systems. No longer confined to the Windows world, OPC UA can now communicate with Linux, macOS, and even embedded systems, making it an essential tool for modern automation systems seeking seamless connectivity.

Extensible and Scalable: Adapting to Your Needs

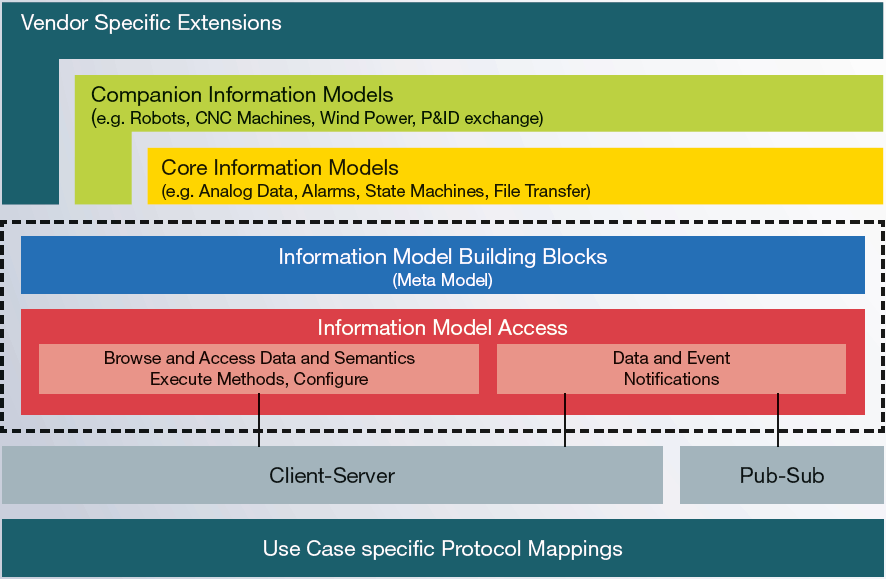

OPC UA is designed to be extensible and scalable, meeting the diverse requirements of industrial automation systems of all sizes. Its modular architecture ensures that it can easily adapt to new technologies and trends, while its support for various data transports (TCP, HTTP, and more) enables it to cater to a wide range of applications.

Security: Fortifying Your Systems

With cyber threats on the rise, OPC UA steps up to the plate with robust security features built into the protocol. From authentication and authorization to encryption and signing, OPC UA ensures that your data remains secure during transmission, granting you peace of mind in an increasingly connected world.

Information Modeling: Making Sense of Complex Data

OPC UA is a trailblazer when it comes to information modeling, supporting complex data structures and the relationships between them. It offers a comprehensive and standardized framework for describing data, making it easier for different systems to interpret and exchange information. This powerful feature paves the way for more advanced and integrated automation solutions.

Interoperability: Bridging the Gap Between Systems

At the heart of OPC UA lies its ability to enable seamless communication between different systems, devices, and software applications. Its platform independence, combined with its advanced information modeling capabilities, allows OPC UA to break down barriers and foster true interoperability in industrial automation. This harmonious collaboration results in increased efficiency, reduced costs, and a more streamlined approach to managing complex operations.

Manufacturing Automation: The Backbone of Industry 4.0

OPC UA has become a cornerstone of modern manufacturing automation, offering seamless connectivity and data exchange between machines, sensors, and software applications. From process control and monitoring to production line optimization and predictive maintenance, OPC UA plays a vital role in driving the digital transformation of the manufacturing sector, pushing the boundaries of Industry 4.0.

Energy Management: Powering the Future

In the realm of energy management, OPC UA takes center stage in smart grid applications. Its robust security features, platform independence, and extensibility make it the go-to choice for managing distributed energy resources, integrating renewable energy sources, and facilitating demand response initiatives. With OPC UA, the energy sector is well-equipped to tackle the challenges of a rapidly evolving landscape.

Building Automation: Creating Intelligent Spaces

When it comes to building automation, OPC UA shines as a powerful tool for managing and optimizing building systems such as HVAC, lighting, and security. By enabling seamless communication between different devices and systems, OPC UA paves the way for energy-efficient, comfortable, and secure smart buildings that cater to the needs of occupants while minimizing their environmental impact.

Other Industries: Broadening Horizons

OPC UA's versatile capabilities have also made it a popular choice in other industries, such as oil & gas, logistics, and transportation. Whether it's monitoring pipeline networks, optimizing warehouse operations, or streamlining traffic management systems, OPC UA is transforming the way businesses operate, driving innovation, and fostering a more connected and efficient world.

Getting Started with OPC UA - Tools, Resources, and Integration

Available Tools and Resources: Jumpstart Your OPC UA Journey

Embarking on your OPC UA adventure is easier than ever, thanks to a plethora of available tools, resources, and support. Popular OPC UA software development kits (SDKs) like those offered by Unified Automation and Matrikon provide robust platforms for building your own OPC UA applications, while open-source libraries such as FreeOpcUa and node-opcua cater to various programming languages and platforms.

If you're looking for a more out-of-the-box solution, many OPC UA servers and clients are available to get you started quickly. Some of these include Kepware's KEPServerEX, Matrikon's OPC UA Tunneller, and Prosys OPC UA Client. In addition, the OPC Foundation's website offers a wealth of information, including technical documentation, sample code, and other resources to help you along your journey.

Below are some products that use OPC UA as a key component of their functionality. These examples span various industries and applications to give you a diverse set of references:

- Siemens SIMATIC S7-1500 PLCs: These controllers are widely used in manufacturing and process automation, and they support OPC UA for seamless communication with other devices and systems.

- Beckhoff TwinCAT 3: Beckhoff's automation software integrates OPC UA for easy communication with other devices, making it an essential tool for building automation, manufacturing, and other applications.

- Kepware KEPServerEX: This industrial connectivity platform provides support for OPC UA, allowing it to connect various devices and systems in a wide range of industries, including oil & gas, power generation, and manufacturing.

- Ignition by Inductive Automation: Ignition is a powerful industrial application platform that supports OPC UA for seamless communication between devices, enabling users to create comprehensive SCADA, HMI, and IIoT solutions.

- Honeywell Experion PKS: Honeywell's distributed control system (DCS) supports OPC UA, making it suitable for various process industries, such as refining, chemical, and power generation.

These products showcase the versatility of OPC UA and how it can be applied across different industries and applications. Including these examples in your blog post will help readers understand the practical use cases of OPC UA in real-world scenarios.

Integration with Other Protocols: The Power of Synergy

One of OPC UA's most impressive features is its ability to work seamlessly alongside other industrial protocols, creating a truly interoperable automation network. Multi-protocol gateways, such as those offered by Sierra Monitor, ProSoft Technology, and Softing, allow OPC UA to communicate with other protocols like Modbus, BACnet, and EtherNet/IP, bridging the gap between disparate systems and devices.

This flexibility ensures that OPC UA can be integrated into a wide variety of automation environments, enhancing data exchange, streamlining operations, and reducing complexity. By embracing OPC UA and its synergistic capabilities, you're well on your way to unlocking the full potential of your industrial automation system.

Conclusion - Embracing the Future of Industrial Automation with OPC UA

In our journey through the world of OPC UA, we've explored the key features that make this protocol a powerful force in industrial automation: platform independence, extensibility, robust security, information modeling, and interoperability. These qualities enable OPC UA to provide seamless communication between various systems, devices, and software applications, enhancing efficiency and reducing complexity.

As you venture into your own automation projects, consider integrating OPC UA for a more streamlined and secure experience. Innovative platforms like Node-RED offer a user-friendly way to connect OPC UA with other protocols and devices, while Flecnode's versatile IoT controller expands the realm of possibilities even further.

Embrace OPC UA and unlock the full potential of your automation network, creating a smarter, more connected future. Happy automating!